-

Melting

- 1 Unit 500 Kg Mono Track

- 1 Unit 1000 Kg Mono Track

2 Unit 1000 Kg Dual Track

- 2 Unit 1500 Kg Dual Track

-

Sand Plant

- Fully Automated Sand Plant from DISA

- Green Sand Multi Controllers

- Sand Coolers from DISA

-

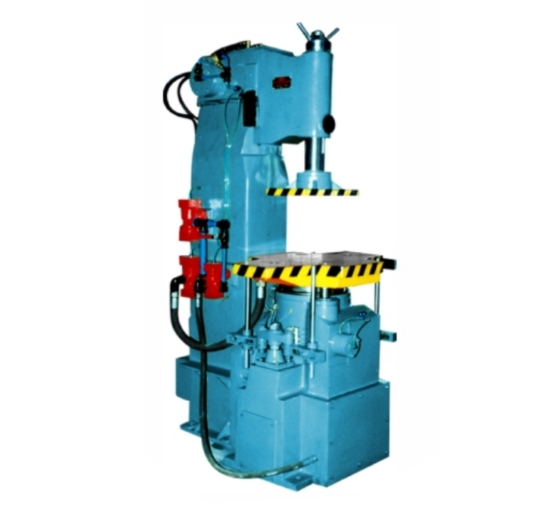

Core Making

- Multitude of CO2 Core,

- Shell & Cold Box Core Machines

Cold box core machines

| Machine Capacity |

No. of Machines |

| 10kg Horizontal |

2 |

| 20kg Vertical |

6 |

| 30kg Horizontal |

1 |

| 100kg Horizontal |

2 |

Shell core machines

| Machine Capacity |

No. of Machines |

| 5kg |

5 |

| 25kg |

1 |

-

DISAMATIC C3 – Fully Automatic VERTICAL 1 Line - Flaskless High-Pressure Moulding

- Mould Size – 650mm x 535mm x 120/340 mm

- Moulding Speed – 250 Moulds / Hour

- Weight Range – 0.5 to 30 Kgs

- Capacity – 16000 MT / Annum

- Grade – Ductile Iron / Grey Iron

-

DISA MATCH 130 - Fully Automatic HORIZONTAL

2 Lines - Flaskless High-Pressure Moulding

- Mould Size – 508mm x 610mm x 300/400mm

- Moulding Speed – 160 Moulds / Hour

- Weight Range – 0.5 to 50 Kgs

- Capacity – 16000 MT / Annum

- Grade – Ductile Iron / Grey Iron

-

Arpa 900 – Jolt and Squeeze Moulding with Flask 4 Lines

- Mould Size –

1 – 970mm x 740mm x 600mm

2 – 970mm x 910mm x 600mm

- Moulding Speed – 40 Moulds / Hour

- Weight Range – 20 to 200 Kgs

- Capacity – 18000 MT / Annum

- Grade – Ductile Iron / Grey Iron